No matter the size of your fleet, in today’s demanding environment, every minute spent rallying resources and manually removing rooftop snow from tractor trailers, trucks and buses cuts into your bottom line and delays getting your fleet where it needs to be – on the road.

Fleet managers and administrators should know two things about their winter operation:

- the operational costs for getting their fleet on the road after a snowstorm, and

- how much could be saved automating your snow removal process

Measure the costs associated with manual and automated snow clearing

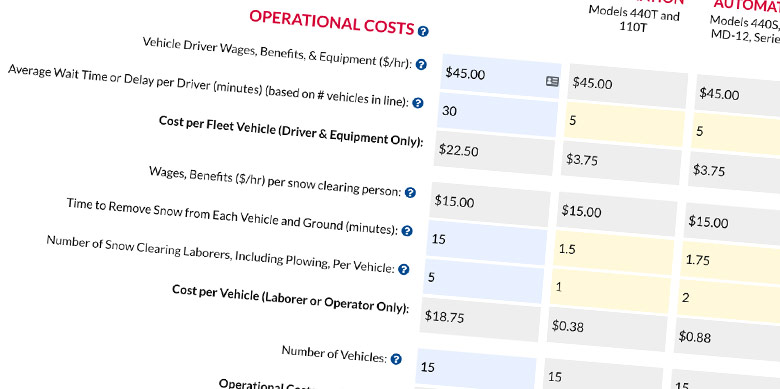

Use our savings calculator to compare the yearly operational costs associated with manual clearing of snow from your fleet vs automated clearing with a FleetPlow. For best information, customize the results by using data from your own operation. Or, if you prefer, use the example data included for truck and bus scenarios.

Over and above these hard savings, FleetPlows can impact your bottom line by reducing additional risks and costs associated with snow removal. With FleetPlow working for your fleet, you’ll

- Reduce risks, liability to motorists and negative publicity caused by ice and snow dislodging from vehicle roofs

- Lower fuel costs

- Prevent injuries to employees and subsequent claims

- Decrease downtime and equipment damage

- Reduce violations and fines to drivers

- Minimize late deliveries and missed appointments

- Lower winter stress and hassle.

Calculate the cost of snow removal

Step One – GATHER seven pieces of data about your operation.

The costs of removing snow fall into three main categories of expenditures.

- Drivers and vehicles waiting or sitting idle during and before their turn to have snow removed

- Laborers who remove snow using manual snow rakes, and

- Ground plow operators removing snow from the ground after it’s been cleared from vehicle rooftops.

The seven pieces of data you’ll need from your current operation:

Vehicle Driver Wages, Benefits, & Equipment ($/hr)

The combined total of the wage and benefits that you pay one vehicle driver per hour, plus average cost to operate one vehicle per hour. (Example based on industry averages: use $62.09 for trucks or $47.15 for buses.)

Truck example includes $32.03/hr for driver wage, $10.83/hr for benefit, and $19.23/hr for equipment.

Bus example includes $17.08 for driver wage/hr, $15.65/hr for benefits, and $14.42/hr for equipment.)

Average Wait Time or Delay per Driver (Minutes) Based on Number of Vehicles in Line

Average time drivers are waiting in line or sitting idle before and during the time their vehicle is cleared of snow. (Example: 60 minutes for trucks or 60 minutes for buses)

Wages, Benefits ($/hr) per Snow Clearing Person:

The combined total of wage and benefits that you pay one laborer per hour to clear rooftop snow. (Example based on industry averages: $34.96 for trucks and buses.)

Example includes $24.13/hr for wage and $10.83/hr for benefits.

Time to Remove Snow from Each Vehicle and Ground (Minutes):

The amount of time it takes to clear one vehicle and the ground area around it. (Example: 40 minutes for trucks and 30 minutes for buses)

Number of Snow Clearing Laborers, Including Plowing, per Vehicle:

Number of laborers it takes to remove snow in the time you indicated in the line above. Include laborers who use ground plows to remove snow around vehicles. (Example: 3 for trucks and 5 for buses.)

Number of Vehicles:

Number of vehicles in your fleet.

Snow Events per Year:

Enter the typical number of winter storms requiring rooftop clearing in your area.

Step Two – ENTER the data into the savings calculator and view the operational cost comparison.

As you enter your data, the savings calculator will generate your annual operational cost to clear snow manually from your fleet.

You’ll also see the projected costs when using a FleetPlow and the savings compared to manual snow removal for one year and for 20 years (the rated life of the machine).

Step Three – EVALUATE your company’s snow removal costs and potential savings.

For most truck and bus operations, evaluating the operational savings is a direct, quick, and important way to conduct a side-by-side comparison of manual rooftop snow removal methods vs. Scraper Systems FleetPlows.

But that’s not the only assessment criteria to use when considering switching to an automated snow clearing solution for your fleet. The indirect costs of manual snow removal can be costly, and should be included in your review.

When you evaluate your manual snow removal costs, consider that FleetPlows also reduce indirect costs of using hand-held rakes and shovels to clear roof-top snow:

Calculate the cost of snow removal

Step Four – Contact us.

Well-managed fleets make automated rooftop snow removal part of a pro-active winter transportation plan. Knowing the numbers helps you evaluate your manual snow removal system. This can be a great starting point for further discussion about putting FleetPlow to work for you.

If you’d like a pdf of your results, provide your contact information and one will be emailed to you.

Contact us to discuss specifications and pricing.

888-340-4344

info@ScraperSystems.com